Introduction

Location data is the new gold in the digital age of information. With the inception of Industry 4.0 in supply chain and logistics, it has become increasingly imperative for logisticians to have a clear and reliable overview of material flow throughout the entire range of operations. Having a dynamic database for the location of assets opens the door for a plethora of business cases, such as inventory management, stock visibility, process flow optimization, and real-time tracking.

Furthermore, every business case has unique system requirements, resulting in the need for multiple positioning technologies that are often proprietary and not compatible with each other. The inability to effectively combine positioning technologies is a significant bottleneck that inhibits organizations from operating smoothly with cutting-edge performance and accurate results.

The Challenge

One of our customers, an international producer and supplier of large-scale mining equipment, was struggling to efficiently locate machine parts and components stored in their distribution center. Assets were packed in crates, and they were transported to storage with forklifts. When an order was received, workers had to tediously search for the asset and manually verify that it was the correct asset for the distribution. This resulted in significant time-loss and increased overhead.

The customer therefore sought to identify the most suitable technology and hardware to be installed and integrated into their existing infrastructure. The overall goal was to reduce search time for specific assets, provide real-time data on inventory to ultimately reduce delays in dispatching.

The Solution

This is where omlox and our DeepHub® came into play. Launched in 2020, omlox is the first open and interoperable standard for real-time location systems.

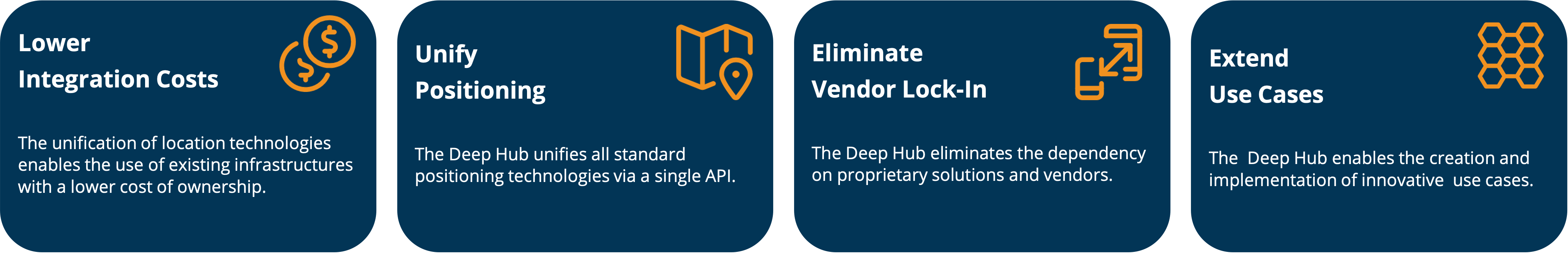

Flowcate’s DeepHub is the premier omlox-compliant middleware that enables the interoperability of all positioning technologies, allowing for the cross-integration of hardware and software components from any vendor. Fundamentally the DeepHub is a location data management platform that can consume any type of real-time location data in order to streamline operational efficiencies and facilitate entirely new use-cases in the framework of Industrial IoT.

To address the customer’s operational inefficiencies, a solution was devised and executed by a group of partners from the omlox ecosystem, where the DeepHub acted as the core of the solution.

The solution was to equip the customer’s forklifts with appropriate hardware that would identify assets and track the location of assets throughout the facility. To accomplish this and avoid manual data entry and human error, sensors and antennas were installed on forklifts. GPS antennas were installed, as they are well-suited to track the location of assets when they are being transported throughout the outdoor area of the facility. In conjunction with this, RFID readers were installed to detect the proximity of relevant RFID tags and store specific asset information.

Here is a short overview of the solution in a nutshell:

- RFID tags are placed on crates and scanned.

- Asset (tag) properties (i.e. machine part information, crate number and RFID) are registered and assigned to trackables in the DeepHub.

- Forklift equipped with a RFID gateway (RFID reader and scanner) and GPS antenna continuously send the forklift’s position to the DeepHub.

- Once an asset is loaded on a forklift, the RFID gateway identifies the asset and associates the RFID tag with the relevant GPS signal.

- The GPS location (together with the RFID tag number) is sent to the DeepHub.

- The warehouse manager can now monitor and identify where a crate and its specific content is located throughout the entire facility in real-time.

Key Takeaways

By connecting the dots between the different partners and technologies, the DeepHub enabled an entirely new solution that filled a clear market need. In this case, the DeepHub harmonized GPS location data with proximity events from RFID tags allowing for seamless location data management.

On one hand, the DeepHub provided the customer with a digital and future-proof platform to track and trace their assets in real-time throughout a facility, thereby significantly reducing operational delays and total cost of ownership. On the other hand, the DeepHub created a future-proof framework free from vendor lock-in and incompatible solutions.

In this way, our technology gives our customers the power and autonomy to choose the positioning technologies, solutions and vendors that meet their unique requirements for asset tracking and logistics.

Discover how the DeepHub can propel RTLS and IoT solutions to the next level. Get in touch with us!

1 thought on “Combining GPS and RFID to Streamline Asset Tracking and Tracing”

Comments are closed.